What once resided firmly in the realm of science fiction – the vision of factories operating hundreds of kilometres above Earth, meticulously crafting high-quality materials – is now a tangible reality, thanks to a pioneering UK-based company. Space Forge, headquartered in Cardiff, Wales, has achieved a significant milestone by successfully sending a compact, microwave-sized factory into orbit. This innovative satellite has not only demonstrated its ability to function in the harsh vacuum of space but has also proven that its internal furnace can be activated and reach searing temperatures of approximately 1,000 degrees Celsius, marking a pivotal step towards off-world manufacturing.

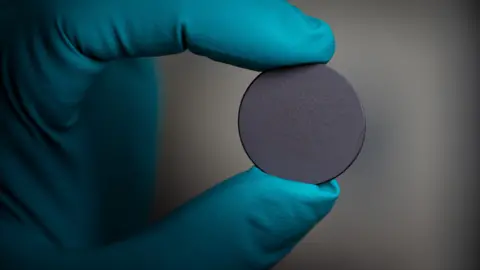

The primary objective of this groundbreaking venture is to manufacture advanced materials for semiconductors. These tiny, yet incredibly powerful, components are the bedrock of modern technology, indispensable in everything from the complex communication infrastructure that powers 5G networks and mobile phones to the sophisticated computing systems driving artificial intelligence and the efficient charging stations for electric vehicles. Their applications extend across myriad industries, including aerospace, defense, medical devices, and consumer electronics, making their quality and availability crucial for global technological advancement.

The unique conditions found in space offer an unparalleled environment for the creation of these highly sensitive materials. Semiconductors are engineered with their constituent atoms arranged in an extraordinarily precise, highly ordered three-dimensional crystal structure. On Earth, the presence of gravity introduces challenges like convection currents and sedimentation, which can disrupt this delicate atomic alignment, leading to imperfections. However, in the microgravity environment of space, these disruptive forces are virtually eliminated. Atoms can align themselves with exceptional perfection, creating a flawless crystalline lattice. Furthermore, the inherent vacuum of space provides an ultra-clean environment, preventing contaminants that could degrade material purity from "sneaking in" during the manufacturing process.

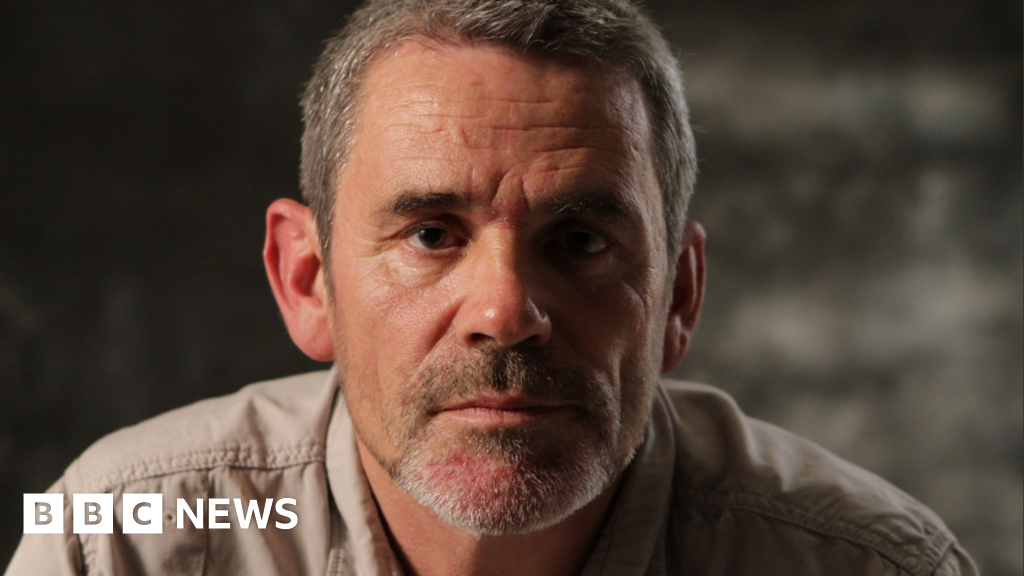

The direct result of these ideal extraterrestrial conditions is a superior product. As Josh Western, CEO of Space Forge, explains, "The work that we’re doing now is allowing us to create semiconductors up to 4,000 times purer in space than we can currently make here today." This astonishing leap in purity and structural integrity directly translates to enhanced performance. Purer, more ordered semiconductors are more efficient, faster, and more reliable, opening doors for next-generation technologies that are currently limited by the capabilities of Earth-manufactured materials. Such advancements could lead to more powerful processors, more efficient power electronics, and breakthroughs in areas like quantum computing and advanced sensing.

The journey to this pivotal moment began when Space Forge’s mini-factory embarked on its mission aboard a SpaceX rocket in the summer. Since its successful deployment into orbit, the dedicated team at Space Forge’s mission control in Cardiff has been meticulously testing and monitoring its various systems. One of the most critical tests involved the activation and heating of the on-board furnace – the core component for material processing.

Veronica Viera, the company’s payload operations lead, vividly recounted the excitement of observing the live data and imagery beamed back from space. She proudly displayed an image transmitted directly from the satellite, captured from inside the furnace itself. This extraordinary photograph showed a brightly glowing sphere of plasma – gas superheated to approximately 1,000 degrees Celsius – illuminating the interior. For Viera, witnessing this image was "one of the most exciting moments of my life." She further emphasized its significance, stating, "This is so important because it’s one of the core ingredients that we need for our in-space manufacturing process. So being able to demonstrate this is amazing." The successful heating of the furnace confirms the viability of critical thermal processes in orbit, a fundamental requirement for producing high-quality materials. It validates years of research, development, and engineering, moving the concept of space manufacturing from theoretical possibility to demonstrated capability.

With this crucial operational success under their belt, Space Forge is now setting its sights on even more ambitious goals. The team is already planning to construct a larger, more robust space factory. This next-generation facility will be designed to scale up production significantly, with the capacity to manufacture enough semiconductor material for an estimated 10,000 chips. Such a scale would begin to tap into the commercial viability of space manufacturing, potentially disrupting existing supply chains and establishing a new paradigm for high-value material production.

However, the journey isn’t solely about making materials in space; it’s also about safely bringing them back to Earth. A critical piece of technology yet to be fully tested is the system designed for atmospheric re-entry. For a future mission, Space Forge plans to deploy a sophisticated heat shield, aptly named Pridwen – a nod to the legendary shield of King Arthur. This advanced shield will be instrumental in protecting the spacecraft and its precious cargo from the extreme temperatures and immense forces encountered as it plunges back through Earth’s atmosphere. Developing a reliable, reusable, and cost-effective re-entry mechanism is paramount for the economic sustainability of space-based manufacturing. It addresses the logistical challenge of transporting finished products from orbit to terrestrial markets, completing the full cycle of off-world production.

Space Forge is not alone in looking skywards for industrial innovation. The burgeoning field of in-space manufacturing is attracting considerable interest from various sectors, with other companies exploring the potential to create everything from advanced pharmaceuticals to artificial tissues in orbit. The microgravity environment, for instance, can facilitate the growth of larger, more perfect protein crystals, crucial for drug discovery, or enable the fabrication of complex biological scaffolds for regenerative medicine that are difficult to produce on Earth.

Libby Jackson, Head of Space at the Science Museum, succinctly captures the essence of this evolving industry: "In-space manufacturing is something that is happening now." She acknowledges that while "it’s the early days and they’re still showing this in small numbers at the moment," the current demonstrations are critical. "But by proving the technology it really opens the door for an economically viable product, where things can be made in space and return to Earth and have use and benefit to everybody on Earth. And that’s really exciting." This sentiment underscores the transformative potential of space manufacturing, not just as a technological marvel, but as a future industry capable of delivering tangible benefits and driving innovation across diverse fields, ultimately enriching life on Earth. The successful operation of Space Forge’s furnace in orbit marks a definitive step into this new industrial frontier, signaling the dawn of an era where humanity’s industrial capabilities are no longer confined to our home planet.