What once seemed like the wildest dreams of science fiction is rapidly becoming a tangible reality, as a pioneering UK-based company takes a monumental leap towards establishing manufacturing capabilities hundreds of kilometres above Earth. Cardiff-based Space Forge has successfully launched a compact, microwave-sized factory into orbit, demonstrating the critical ability to ignite its furnace and achieve searing temperatures of around 1,000 degrees Celsius. This breakthrough represents a pivotal step in their ambitious plan to produce ultra-high-quality materials for semiconductors in the unique environment of space, destined to revolutionise electronics back on our home planet.

The concept of orbiting factories, silently churning out advanced components, has long captivated innovators and futurists. Now, Space Forge is at the forefront of transforming this vision into a commercial enterprise. Their inaugural orbital factory, a testament to ingenious engineering and miniaturisation, embarked on its journey aboard a SpaceX rocket earlier this year. Since its deployment, the dedicated team at Space Forge’s mission control in Cardiff has been diligently testing its systems, culminating in the triumphant activation of its internal furnace. This successful test confirms the fundamental capability required for in-space material processing, opening doors to a new era of industrial production.

The primary objective of Space Forge’s celestial manufacturing venture is the creation of advanced materials for semiconductors. These tiny, yet incredibly powerful, components are the bedrock of modern technology, powering everything from the smartphones in our pockets to the vast global communications infrastructure, sophisticated computing systems, and cutting-edge transport solutions. The pursuit of perfection in semiconductor materials is relentless, and space offers an unparalleled advantage.

Conditions in the vacuum of space are uniquely suited for the meticulous process of growing semiconductor crystals. On Earth, gravity introduces imperfections: molten materials experience convection currents, and heavier elements can settle, leading to structural flaws in the resulting crystal lattice. In the microgravity environment of orbit, these disruptive forces are absent. Atoms are free to arrange themselves in a far more ordered and uniform three-dimensional structure, aligning with unprecedented precision. Furthermore, the hard vacuum of space acts as a natural, pristine cleanroom, eliminating the airborne contaminants that plague terrestrial manufacturing facilities and can introduce impurities into sensitive materials.

Josh Western, CEO of Space Forge, articulates the profound impact of these advantages. "The work that we’re doing now is allowing us to create semiconductors up to 4,000 times purer in space than we can currently make here today," he explains. This staggering improvement in purity and structural integrity translates directly into superior performance. Terrestrial semiconductors, even those produced in highly controlled environments, are subject to microscopic defects that can limit their efficiency, speed, and reliability. Space-grown materials, with their near-perfect atomic alignment and freedom from contaminants, promise to dramatically enhance the capabilities of electronic devices.

Such high-purity semiconductors are not merely incremental improvements; they represent a fundamental leap forward. They are critical for the next generation of technologies that demand extreme performance and efficiency. Imagine 5G towers that offer even faster, more reliable mobile phone signals, electric vehicle chargers that operate with unprecedented speed and minimal energy loss, or avionics systems in the latest aircraft that are more robust and responsive than ever before. Beyond these immediate applications, these ultra-pure semiconductors could unlock new possibilities in fields like quantum computing, advanced AI processors, high-frequency communications, and sophisticated medical imaging devices, where every atomic imperfection can hinder performance.

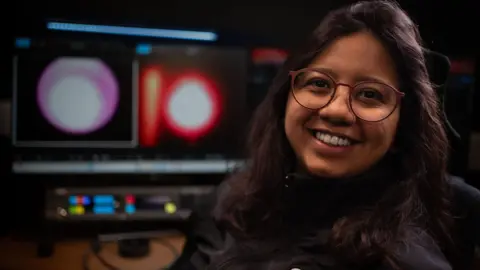

The successful operation of the furnace was a moment of immense validation for the Space Forge team. Veronica Viera, the company’s payload operations lead, shared the excitement of witnessing this milestone from their Cardiff mission control. She recounted the thrill of receiving images beamed back from the satellite, showing the interior of the furnace. In these images, plasma – a superheated gas maintained at approximately 1,000 degrees Celsius – glowed brightly, confirming that the critical heating element was functioning precisely as intended. "This is so important because it’s one of the core ingredients that we need for our in-space manufacturing process," Viera explained, her voice conveying the sheer elation. "So being able to demonstrate this is amazing." The vivid, incandescent plasma captured from orbit was not just a pretty picture; it was concrete proof that the foundational physics and engineering required for their space factory were sound.

This initial success paves the way for increasingly ambitious undertakings. The team is already planning to design and build a larger, more capable space factory. This next-generation orbital facility would aim to significantly scale up production, with the goal of manufacturing enough semiconductor material for 10,000 chips per mission. Such a scale would begin to make a meaningful contribution to the global semiconductor supply chain, which has recently faced significant disruptions and geopolitical pressures, highlighting the strategic importance of diversified manufacturing capabilities.

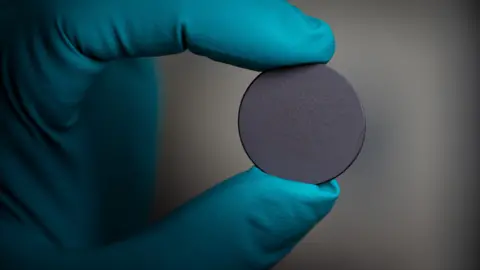

However, manufacturing in space is only half the challenge; the valuable materials must also be safely returned to Earth. Space Forge is developing and testing advanced re-entry technology for this purpose. A crucial component of this system is a specially designed heat shield, evocatively named Pridwen, after the legendary shield of King Arthur. This shield is engineered to protect the spacecraft and its precious cargo from the ferocious temperatures and immense aerodynamic stresses it will encounter as it plunges back through the Earth’s atmosphere. Successfully demonstrating the reliability and reusability of such a re-entry system will be another critical milestone for the company, ensuring that the benefits of space-made materials can be brought directly to terrestrial industries and consumers.

Space Forge is not alone in recognising the vast potential of in-space manufacturing. A burgeoning ecosystem of companies and research institutions globally is looking skywards, exploring how the unique environment of microgravity and vacuum can facilitate the production of an array of high-value goods. From pharmaceuticals, where the absence of gravity can allow for the growth of larger, more perfect protein crystals for drug development, to artificial tissues for medical research and regenerative medicine, the possibilities are extensive. Advanced alloys with novel properties, ultra-pure optical fibres for high-speed data transmission, and even complex biological constructs could all benefit from orbital production.

Libby Jackson, head of space at the Science Museum, underscores the significance of these developments. "In-space manufacturing is something that is happening now," she affirms, acknowledging that while it’s still in its early stages and production numbers are currently small, the foundational technology is being rigorously proven. "But by proving the technology it really opens the door for an economically viable product, where things can be made in space and return to Earth and have use and benefit to everybody on Earth. And that’s really exciting." This economic viability is key to moving beyond experimental prototypes to a thriving, sustainable space industry that complements and enhances Earth-based manufacturing.

The implications of this burgeoning field are far-reaching. It promises to diversify manufacturing supply chains, create entirely new markets and industries, and potentially lead to materials with properties unattainable through conventional terrestrial methods. While challenges such as the cost of launch, power requirements in orbit, and radiation exposure remain, the rapid advancements in space technology, exemplified by companies like Space Forge, are systematically addressing these hurdles. The successful activation of a 1,000C furnace in orbit by a UK company marks a profound moment, signalling not just the dawn of a new industrial frontier, but a tangible step towards a future where the resources and unique conditions of space are harnessed for the direct benefit of humanity on Earth.