What once sounded like the wildest imaginings of science fiction – a fully operational factory, orbiting hundreds of kilometres above Earth, dedicated to churning out high-quality materials – is now a tangible reality, thanks to the pioneering efforts of a Welsh company. Cardiff-based Space Forge has taken a monumental leap forward in the burgeoning field of in-space manufacturing, successfully deploying a compact, microwave-sized factory into orbit and demonstrating its core functionality: a furnace capable of reaching scorching temperatures of around 1,000C. This groundbreaking achievement marks a pivotal moment, paving the way for a new era of industrial production that leverages the unique conditions of space to create materials of unparalleled purity and performance.

The primary objective of this orbital factory is to manufacture advanced materials for semiconductors. These tiny, yet incredibly powerful, components are the bedrock of modern technology, found in everything from the smartphones in our pockets and the sophisticated communication infrastructure that connects our world, to the complex computing systems driving artificial intelligence and the advanced electronics powering electric vehicles and next-generation aircraft. The ability to produce superior semiconductors in space could revolutionise numerous industries back on Earth, addressing critical supply chain issues and unlocking new capabilities for future technologies.

The rationale behind venturing into space for manufacturing these crucial materials lies in the extraordinary conditions found beyond Earth’s atmosphere. Semiconductors derive their electrical properties from the precise arrangement of their constituent atoms in a highly ordered, crystalline three-dimensional structure. On Earth, the omnipresent force of gravity introduces microscopic defects and imperfections during the cooling and solidification processes, leading to slight irregularities in the atomic lattice. Even the most advanced terrestrial manufacturing facilities struggle to entirely mitigate these gravitational effects, which can subtly diminish the performance and efficiency of the final semiconductor product.

In the microgravity environment of space, however, these limitations vanish. When materials are melted and then allowed to solidify in near weightlessness, the atoms are able to align themselves with remarkable precision, forming crystal structures that are virtually perfect. This absence of gravitational influence means there are no forces pulling atoms out of their ideal positions, resulting in an almost flawless atomic arrangement. Furthermore, the inherent vacuum of space offers another critical advantage: it acts as a pristine, contaminant-free environment. Unlike terrestrial factories, which must employ elaborate and costly cleanroom technologies to prevent even microscopic dust particles or atmospheric gases from interfering with sensitive manufacturing processes, space inherently provides an ultra-clean, sterile environment, ensuring that no impurities "sneak in" to compromise the material’s purity.

Josh Western, CEO of Space Forge, underscores the profound impact of these unique spatial conditions. "The work that we’re doing now is allowing us to create semiconductors up to 4,000 times purer in space than we can currently make here today," he explains. This staggering improvement in purity and structural integrity translates directly into semiconductors with vastly superior performance characteristics – greater efficiency, faster processing speeds, and enhanced reliability. These ultra-pure semiconductors are not just an incremental improvement; they represent a step-change that could enable advancements previously thought impossible. Imagine a future where your 5G tower delivers even more robust signals, where electric vehicle chargers operate with unprecedented efficiency, and where the next generation of aerospace and defence systems achieve new levels of capability. The applications are extensive, touching every facet of our increasingly interconnected and technology-dependent lives.

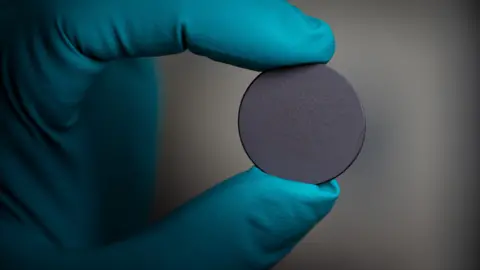

The journey to this orbital milestone began with the mini-factory launching aboard a SpaceX rocket earlier in the summer. Since its deployment, the dedicated team at Space Forge’s mission control headquarters in Cardiff has been diligently testing its various systems, meticulously monitoring its performance and validating its capabilities from afar. Among the most thrilling confirmations was the successful activation of the furnace. Veronica Viera, the company’s payload operations lead, vividly recounts the excitement of receiving the crucial telemetry and imagery from space. She proudly displays an image beamed back directly from inside the furnace – a striking visual of glowing plasma, gas heated to the astonishing temperature of approximately 1,000C.

"This is so important because it’s one of the core ingredients that we need for our in-space manufacturing process," Viera explains, her enthusiasm palpable. "So being able to demonstrate this is amazing." The sight of the incandescent plasma, a testament to the furnace’s operational success, was, for her, "one of the most exciting moments of my life." This successful demonstration of extreme heat generation in orbit is a critical technological de-risking step, proving that the fundamental processes required for advanced material synthesis can indeed be carried out in the harsh environment of space. It validates years of research, development, and engineering effort, moving the concept of space factories from theoretical potential to practical application.

Looking ahead, Space Forge is already setting its sights on ambitious future endeavours. The current mission serves as a vital proof of concept, and the team is now planning to construct a significantly larger space factory. This next-generation orbital facility will be designed with a substantially greater capacity, envisioned to manufacture enough semiconductor material to produce as many as 10,000 individual chips per batch. Scaling up production will be crucial for achieving commercial viability and making a meaningful impact on global supply chains. However, a significant technological hurdle remains: the safe and reliable return of these valuable, space-manufactured materials to Earth.

For future missions, Space Forge plans to deploy a sophisticated heat shield, aptly named Pridwen – a nod to the legendary shield of King Arthur, symbolising protection and resilience. This bespoke heat shield will be essential for safeguarding the spacecraft and its precious cargo from the extreme temperatures and immense aerodynamic forces it will encounter during its fiery re-entry into Earth’s atmosphere. Developing and rigorously testing this re-entry technology is a complex engineering challenge, requiring meticulous design, advanced materials science, and precise atmospheric modelling to ensure a controlled and safe descent. The successful demonstration of Pridwen will be the final piece of the puzzle, completing the end-to-end cycle of in-space manufacturing, from production to delivery back to terrestrial customers.

Space Forge is not alone in recognising the immense potential of manufacturing beyond Earth. A growing number of innovative companies globally are turning their gaze skywards, exploring a diverse range of products that could benefit from the unique conditions of microgravity and vacuum. From pharmaceuticals, where the absence of gravity can lead to more uniform crystal structures in drug compounds, potentially improving efficacy and stability, to the creation of artificial tissues and organs for medical research and transplantation, the possibilities are vast and rapidly expanding. The "new space race" is not just about rockets and exploration; it’s increasingly about leveraging space as a novel industrial environment.

Libby Jackson, head of space at the Science Museum, articulates the broader significance of these developments. "In-space manufacturing is something that is happening now," she affirms, highlighting the tangible progress being made. While acknowledging that "it’s the early days and they’re still showing this in small numbers at the moment," Jackson remains optimistic about the future. She emphasises that "by proving the technology it really opens the door for an economically viable product, where things can be made in space and return to Earth and have use and benefit to everybody on Earth. And that’s really exciting." This vision of an orbital economy, where specialized factories produce materials superior to anything achievable on Earth, promises to transform industries, drive innovation, and ultimately deliver profound benefits to humanity. The successful operation of Space Forge’s 1,000C furnace in orbit is more than just a technical triumph; it is a powerful harbinger of this extraordinary future.